Heavy Plant and associated equipment vary so much in design, layout, size, age, conditions and even locations that any one factor can have a significant bearing on how a machining problem is tackled, especially during breakdowns. Plant maintenance departments will attend to whatever first-aid they can manage, but with the recognized advantage of calling in specialist services time can be saved and costs reduced.

The advantages are significant when compared win the alternative which could otherwise involve stripping down, transporting to a machine shop, returning to site, reassembly, as compared to taking a special purpose machine to the job.

Our engineers co-operate with clients on new plant and modifications, to give the most viable solutions for on-site machining. The service division offers a rapid response for maintenance and breakdown situations.

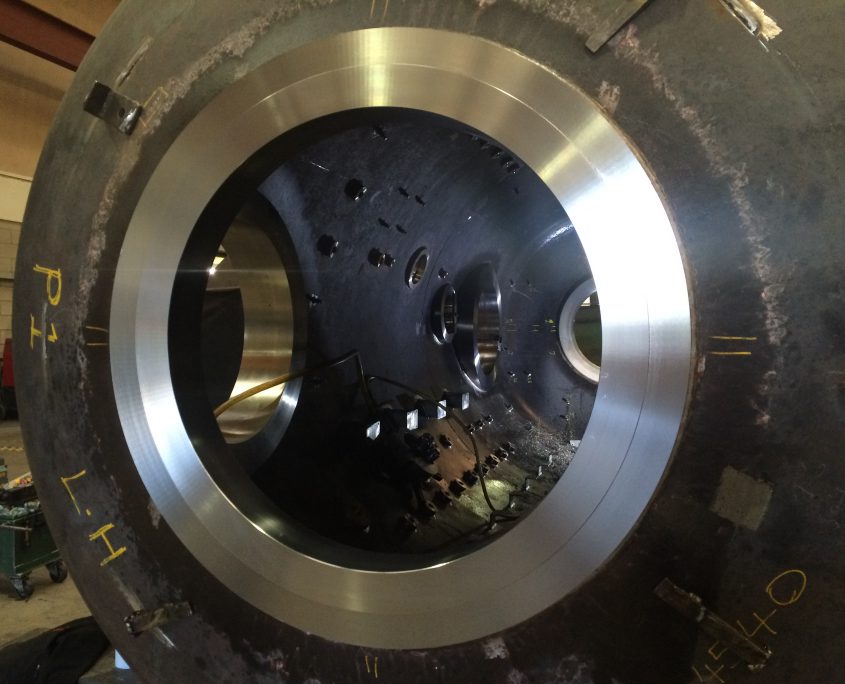

Most of the machines and equipment used have been designed and manufactured by Destec Engineering Ltd. Maximum versatility and adaptability combined with accuracy and a good surface finish ensure most In-Situ operations can be handled effectively and quickly.

Destec Engineering has carried out hundreds of conventional and unusual machining contracts on vessel and heat exchanger closures, piework flanges, nozzles, valve seats, offshore wind turbines etc, incorporating all types of profiles, such as spigots, recesses, tapers, grooves ranging from a fine to a gramophone surface finish.

Destec on-site machining includes:

Destec portable machines are equipped with variable speeds and automatic feeds to give good accurate surface finishes. Power feeds tool posts can be set for tapers, profiles, spigots and boring.

For manways including spigoted joints. Destec’s purpose built machines generate true ellipses and machine to both fine and “Gramophone groove” finishes.

Precision in-line boring in any plane.

Pipe Cutting and Weld Preparation

Destec’s patented tooling system will cut the thickest pipes in the hardest materials.

Universal milling machines that cut in any position with large feed ranges to limit set ups. Our milling machines working range is up to 6 metres.

Keyway Cutting

Direct onto shafts with minimum clearance required.

Drilling and Reaming

We have portable equipment to cover all diameters and depths.

Thread Cutting and Tapping

Screw cutting of internal threads in either smooth bores or the rectification of damaged threads. We also machine tap when required

Trepanning

Machines can be adapted for trepanning to reduce machining cost and down time.

Welding

Welders are available for on-site weld overlay

Download the Destec On-Site Services PDF

Destec has designed, developed and built special purpose machines for the oil, petrochemical and nuclear industries.

This was a natural progression from the in-house designed and built on-site portable machines that have been used by our own technicians over the last 25 years. Read More.

We have the experience and equipment for all bolt tensioning on site. Read More.

Destec experienced technicians using proven leak sealing systems will keep your plant operational and reduce running costs through wastage. Read More.

Polymer Repairs and Coating

Please contact us for further information.

For more information about our products and services call us on 01522 791721 or email us at service@destec.co.uk