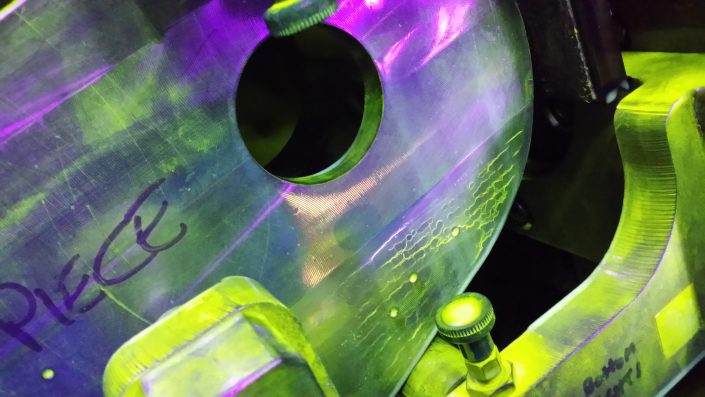

MPI

MPI can be undertaken utilizing the Company’s unique Karl Deutsch Deutroflux UWS 1500 bench, which simultaneously applies field current in circular and axial direction, ensuring full component coverage for flaws in any direction. Component capacity of 1500mm length, with coil dia size of 40mm ensures large components can easily be processed, and revolving heads ensure full 360° viewing. Threader bars are available in order to increase small component throughput.

PLC controls ensure repeatable parameters, and all magnetization data can be downloaded in order to produce comprehensive certification.

For components that cannot be taken to a dark room (such as in- service), the yoke and black ink method is available.

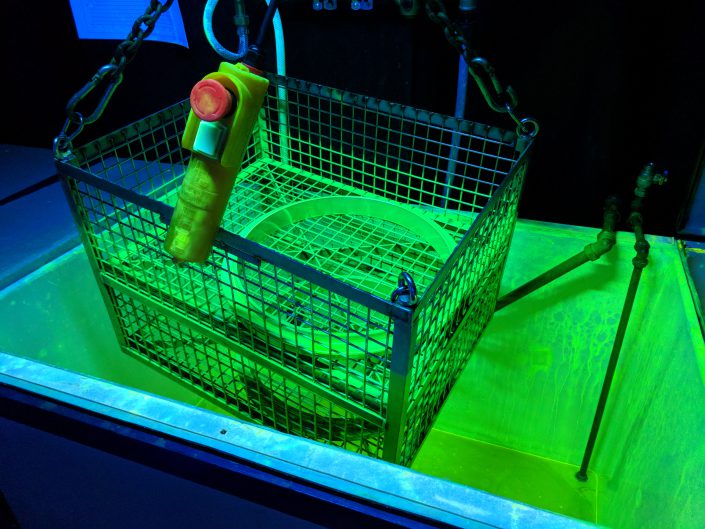

DPI

DPI can be undertaken in both colour contrast water washable and hydrophilic post emulsifiable techniques.

The hydrophilic post emulsifiable technique has tank capacities of 100 gallons, allowing rapid processing of small high volume components. For larger components, and for where dark room facilities are not available (such as in service/situ), colour contrast provides an ideal solution.

Where surface breaking cracks are found, these can be gauged using a crack depth meter, to allow accurate assessment as to the relevance and serviceability of parts.

UT

UT is undertaken using a Sonatest Sitescan 123W flaw detector unit and appropriate probes, ensuring as close to 100% sweep as geometry allows.

NDE operators are qualified to both PCN and approved written practice schemes to Level II, allowing operation in a variety of industries, including petrochemical, rail, and aerospace.

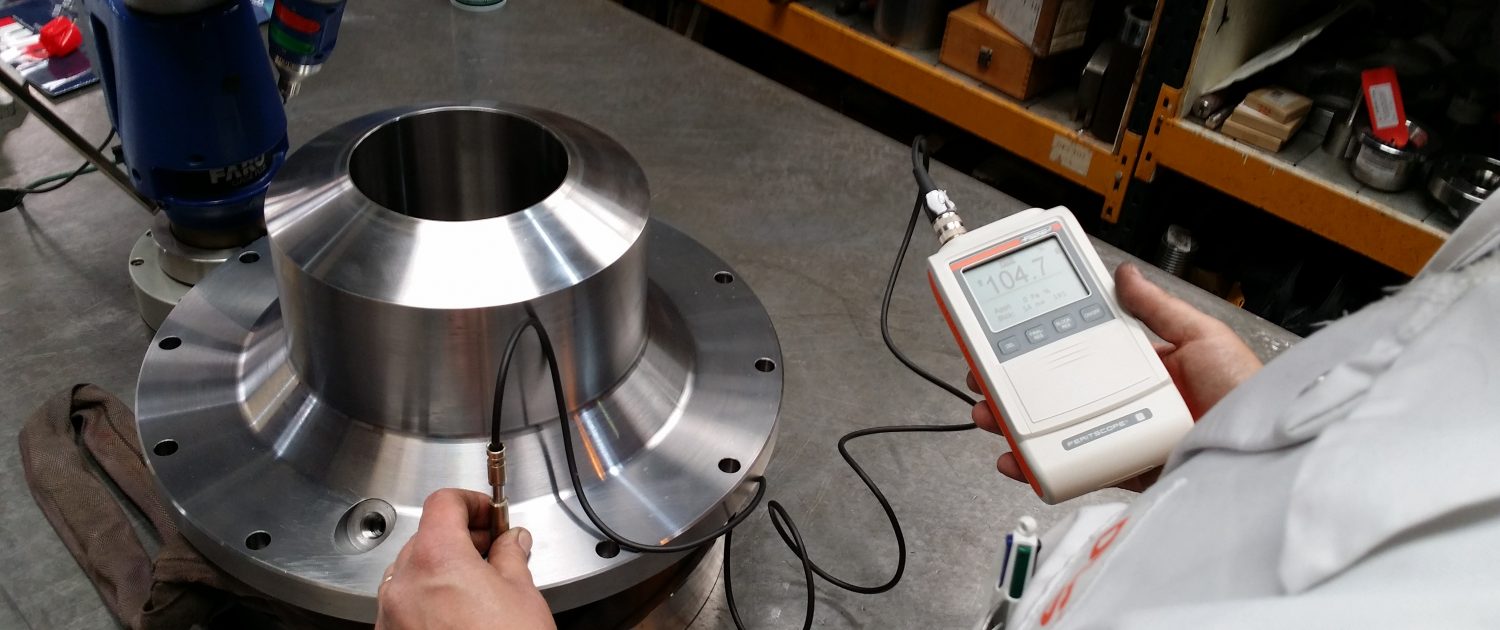

Ferrite Testing

A FERITSCOPE® FMP30 is utilized for fast, non-destructive and accurate measurement of ferrite content on-site or in shop. Content can be measured either in Ferrit-percentage “%Fe” or in Ferrit numbers “FN”. Measurement can be undertaken on welds, cladding, or base materials in austenitic and duplex steels. Certification available.

CMM Arm Inspection.

Our Faro Gage Arm is a portable measurement facility for clients requiring CMM measurement , enabling metrology to be brought to the application rather than the reverse.

This can be used for :

- Reverse engineering

- Resolving dimensional disputes.

- Providing full dimensional reporting without the need for a variety of equipment.

The Gage has a range of 1.2metres.

For more information about our products and services call us on 01522 791721 or email us at sales@destec.co.uk