Destec seal rings are being used as original equipment in client’s products and are also in service as replacement for original troublesome joints.

Many clients have drawn on Destec’s specialised knowledge and experience on the use of High Pressure and High Temperature metal-to-metal static sealing.

Destec have developed a sealing system which uses a modified cone ring giving excellent leak tightness properties under the most severe conditions of pressure, temperature, thermal cycling and shock.

With conversions of old joints to Destec seals our engineers carry out the design modifications in accordance with established codes and standards, whilst the practical site work is handled by Destec’s on-site machining service using portable machines to carry out the modification and re-build on site.

Destec’s seal rings have the following features:

- Sizes from 10mm to 2150mm currently in service.

- The higher the pressure the more attractive the Destec seal design becomes as internal pressure intensifies the sealing action.

- The Destec all metal seal ring can be used at high temperatures. Maximum service temperature being limited by the seal material selected. Materials range from carbon and alloy steels through to Inconel, with a range of coatings for lubrication.

- The sealing system is extremely leak tight under the most severe conditions of pressure, temperature, vacuum, and is suitable for nuclear applications.

- Cold quench conditions and thermal cycling are the cause of most leakage problems where conventional compressible type joints and seal materials are used. The additional flexibility of the Destec seal ring ensures a tight seal during thermal transient conditions.

- Compact and lighter flange designs can usually be achieved by using Destec’s seals. Fluid seal areas and joint loads are lower when compared with conventional compressible type joints.

- The all metal Destec seal ring is elastic in design and on dismantling reverts to its original form ready for re-use. All seals of a given size are interchangeable without any pre-fitting.

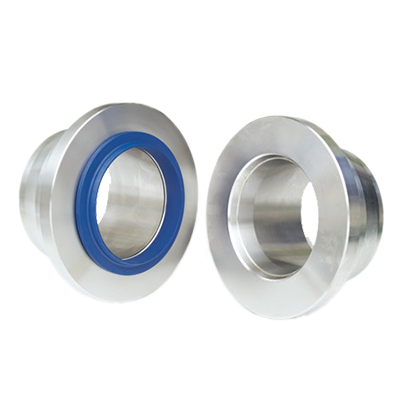

Up to 850 mm diameter Destec Seal Rings are supplied as a double cone ring.

Sizes of standard seal rings go up in 5 mm steps and closely match the bore of the component. If an exact match is required we will supply a purpose designed seal ring.

Seal rings over 200 mm diameter may be supplied with a central rib. This enables us to maintain a high seating stress whilst keeping the overall width of the seal ring down to a reasonable size.

The fluid seal diameter of the Destec is close to the bore minimising the end loads across the joint. The internal pressure area is larger than the seating area and increases the seating stress by approximately four times the pressure.

Joint faces make contact outside the seal faces providing a datum and preventing external forces from being transmitted through the sealing area.

Seal Ring Retainers

To assist assembly the seal rings can be retained in one of the flanges. This has proven to decrease assembly times when working under difficult conditions,

for example, on work barges connecting flexible hoses.

The retainers are also designed to be fitted by ROV where the Seal Rings can be removed by a collet gripping the bore.

Orifice Seal Rings and Blinds

Destec Seal Rings can be designed to incorporate orifice plates, chokes or blinds. Large orifices requiring seals 200 mm and above, would normally be supplied as a wafer to fit between flanges and use two Seal Rings. This also applies to blinds which would have pressure limitations if incorporated as part of a Seal Ring.

Shrouded Seal Rings

Where there is severe corrosion or erosion the Seal Ring can be protected by fitting sleeves in the bore. Shrouds in special materials are often fitted with lined pipe.

The standard Destec Seal Ring is satisfactory for normal pipe corrosion allowances.

Heavy Duty Seal Rings

Destec manufacture a range of heavy duty Seal Rings to meet the requirements of very deep sea applications. These Seal Rings are designed to take high external pressure and will take high flange shear loads without using spigots.

Colour Coding of Seal Rings – Seal Ring PTFE coatings are colour coded in relation to the base material to aid identification.

| Seal Ring Material | Seal Ring PTFE colour |

| Low Alloy Steel / Carbon Steel: AISI 4140 Martensitic Steel: A564-630 Austenitic Steel: A638-660 Nickel Chromium: X750, 718, 725 Duplex & Super Duplex: F51, F55 Nickel Chromium: 625 PLUS |

Violet Blue Olive Grey Ruby Red Grass Green Black Light Orange |

For more information about our products and services call us on 01522 791721 or email us at sales@destec.co.uk

Making and Maintaining the right connection.

DESTEC ENGINEERING LTD

Five Mile Lane, Washingborough,

Lincoln. LN4 1AF. UK

Tel: +44 (0) 1522 791 721

Fax: +44 (0) 1522 790 033

Email: sales@destec.co.uk

For On-Site Services

Email: service@destec.co.uk

Out Of Office Contact:

+44 (0) 7854857865

Office Hours

Mon-Thu: 08:30-17:00

Fri: 08:30-16:30

Sat-Sun: Out of office contact